Manufacturing the donkey cart and ambulance

Practical Action

Part Material and Notes

No

off

A Mild Steel Flat Section

4

(Ambulance Brackets)

B Mild Steel Right angle

4

section (Ambulance frame)

Length

(mm)

50

Width or

cross

section

(mm)

50 x 50

Depth /

Wall

Thicknes

s (mm)

3

ø(mm)

1800

25.4 x 1.5

25.4 (1')

C Mild Steel Right angle

3 1510 25.4 x 1.5

section (Ambulance frame)

25.4 (1')

D Mild Steel Right angle

4 300 25.4 x 1.5

section (Ambulance frame)

25.4 (1')

E Mild Steel Flat Section

3 296 50

1.5

(Ambulance frame support

strap)

F Wire Mesh

2 1794 294

1

G Wire Mesh

1 1504 294

1

H Planks of Wood (dimensions 8

1500 200

15

given are approx, wood most + 1

cover an area of 1500 mm x cut

1790 mm)

to

size

I Mild Steel Flat Section

2 1796 20

2

(wood support)

J Mild Steel Round Section 2

260

(Roof support)

K Material (Cotton Cloth)

Cut

to fit

L Mild Steel Right angle

1 275 25.4 x 3

section (Seat Support)

25.4 (1')

M Mild Steel Right angle

2 300 25.4 x 3

section (Drivers Seat)

25.4 (1')

N Mild Steel Right angle

1 225 25.4 x 3

section (Drivers Seat)

25.4 (1')

10

6.2 Instructions

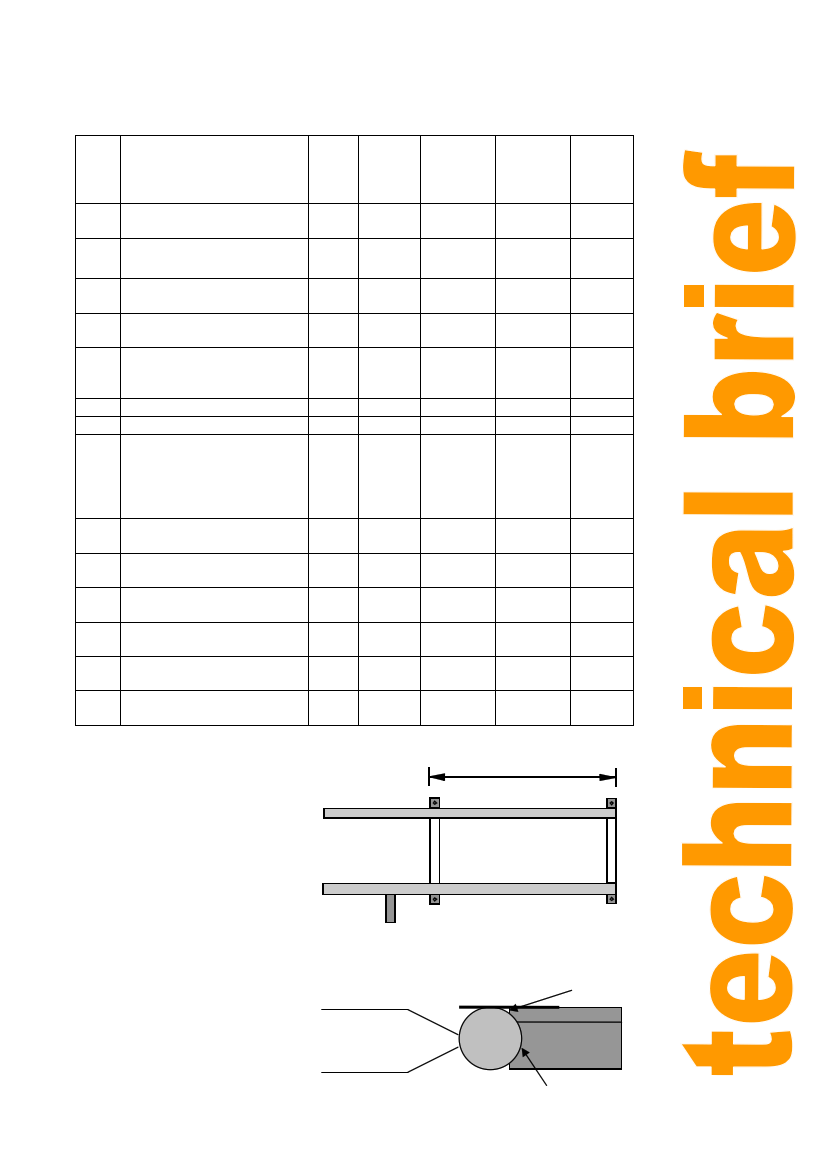

Diagram 14. Plan view of cart frame with brackets

2000 m

1. Weld each of the four

ambulance support brackets to

the side of the cart program (Part

A).

2. To make the driver seat

support bracket (Part L) mark the

shape of the curved surface of the

main frame bar on to one end of

Part L). Using the angle grinder

grind part so that it has a clear

curved surface which can be

welded flush to the mainframe.

See diagram 14 and 15. This

Diagram 15. View from the front of the cart

showing angle iron for seat support

Flush

surface

Part L with curved surface welded to

12 the side of the cart mainframe